Hain Daniels has enhanced the physical work environment by implementing an automated palletiser from DAN Palletiser. This system replaces manual handling of buckets and cans. The specially designed palletiser ensures that palletising can keep pace with production at one of England's largest food producers.

Improved work environment

Handling various products on one line

Stable handling of buckets and cans

Streamlined production line

Physically demanding work involving heavy lifting and handling, along with challenges in keeping up with production.

Fully automated palletising system that handles multiple products on a single production line.

Replacement of strenuous manual labour, significant improvement in production efficiency, and enhanced competitiveness.

Food manufacturer Hain Daniels Group produces its own product lines and supplies private label brands of food and beverages to the UK market. Like many other large-scale production companies, Hain Daniels recognises the benefits of automation. Therefore, the company has chosen to fully automate parts of its production with a palletiser.

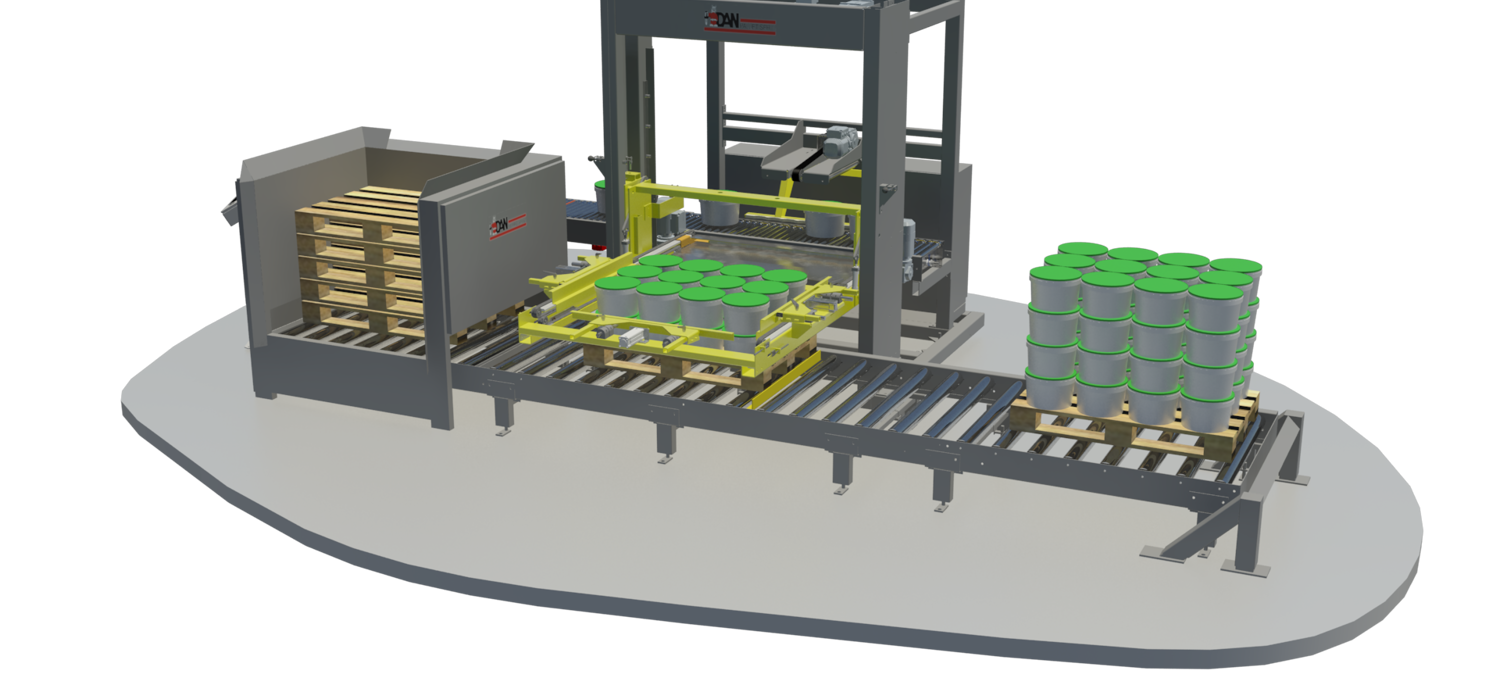

Last year, Hain Daniels implemented an MK4 palletiser, specially designed for palletising conical cans and plastic or metal buckets. When delivering such a palletiser, there is often a need to customise it to fit the specific production line, which was also the case with Hain Daniels.

”For Hain Daniels, we have delivered a specially customised solution as part of the company's brand-new bucket line. The palletiser is designed to palletise both 12.5 L plastic buckets and shrink-wrapped cardboard trays containing four cans,” tells Simon Rune Sørensen, Sales Sanager at DAN Palletiser and explains further:

”With the palletiser, Hain Daniels has ensured stable handling of buckets and cans, gently placing them on pallets at the end of the production line.”

According to Lee Holman, Head of Products at Hain Daniels, it's not just the buckets and cans that are treated with care through the palletiser.

"For us, the palletising solution is an ideal one as it replaces strenuous manual labour. This means that the physical work environment improves, and our employees are spared from heavy lifting and awkward twisting of the back,"

Lee Holman, Head of Products at Hain Daniels

With the implementation of the palletiser, there are more benefits than just the improvement of the physical work environment. Allowing the palletiser to handle monotonous tasks streamlines the production line, and according to Lee Holman, this is crucial for the company:

"By outsourcing the palletising task to an automatic palletiser, we can produce even more in a shorter time than with manual labour. The advantage of an automated palletising solution is that it can work around the clock,"

Lee Holman, Head of Products

"We can palletise goods in the evening and night hours—even on weekends—at a low hourly cost. This increases our competitiveness and the ability to keep up with rising demand."

Contact us

We are ready to answer your questions

as well as take a non-binding talk about

the possibilities for automatic

palletising in your company.